Variable speed drives (VSDs) are integral components in modern industrial and commercial applications, enabling the precise control of motor speeds. They play a significant role in optimizing operations and improving energy efficiency. But what makes VSDs so essential, and why should businesses consider reliable solutions like Vacon?

Importance of Variable Speed Drives

Benefits of Using Variable Speed Drives

Variable Speed Drives (VSDs) offer numerous benefits:

- Energy Savings: One of the most notable advantages is their ability to reduce energy consumption by matching motor speed with the actual demand of the process.

- Enhanced Control: VSDs allow for smooth and precise adjustments in speed, improving the overall control of machinery and equipment.

- Reduced Wear and Tear: By running motors at optimal speeds, VSDs can extend the lifespan of machinery, reducing maintenance needs.

Key Applications of Variable Speed Drives

Industrial Applications

VSDs are used across various industries, including manufacturing, HVAC systems, water treatment, and more. They are especially valuable in processes where variable load requirements exist, such as:

- Pumps: Adjusting the flow rate as needed.

- Fans: Regulating air circulation and energy use.

- Conveyors: Controlling the speed of items being moved.

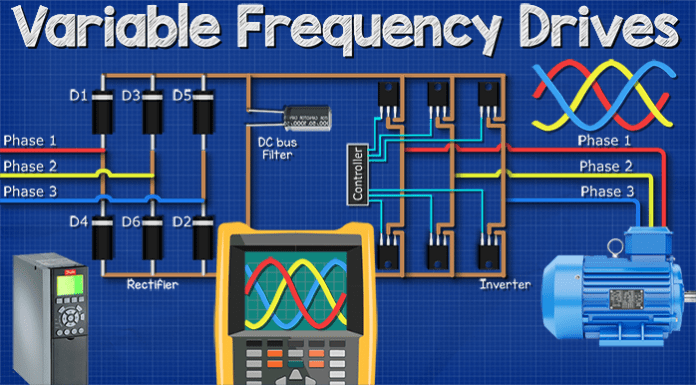

How Variable Speed Drives Work

Basic Working Principles

Variable Speed Drives operate by converting electrical power into a variable frequency output. The primary components include:

- Rectifier: Converts incoming AC (alternating current) to DC (direct current).

- Inverter: Converts DC back to AC at the desired frequency and voltage.

- Controller: Regulates the output frequency and voltage to adjust the speed of the motor.

Benefits of Variable Speed Drives

Energy Efficiency

The primary reason businesses opt for VSDs is energy efficiency. By adjusting the speed of the motor to the specific load, energy use is minimized, leading to cost savings.

Process Control

Variable Speed Drives offer precise control over motor speed, which is crucial for processes that require variable operation. This enhanced control translates to better product quality and improved overall process stability.

Equipment Longevity

Constantly running a motor at a fixed speed can lead to unnecessary wear and tear. By optimizing motor operation, VSDs help prolong the lifespan of machinery and reduce maintenance costs.

Key Features of Vacon Variable Speed Drives

Overview of Vacon’s Technology

Vacon, a prominent name in the field of variable speed drives, stands out for its high-quality and advanced drive solutions. Their products incorporate state-of-the-art technology designed to deliver efficiency and reliability.

Advantages of Choosing Vacon

Choosing Vacon for VSDs offers various benefits:

- Energy Efficiency: Vacon drives are engineered for optimal energy use, contributing to significant cost reductions.

- User-Friendly Interface: Their intuitive control panels and user interfaces simplify operation and maintenance.

- Advanced Control Features: Vacon’s drives come with smart algorithms that adapt to changing load conditions, optimizing performance.

Why Choose Vacon for Variable Speed Drives?

Reliability and Quality

Vacon’s reputation for high-quality products is well-earned. With robust construction and rigorous testing, their drives are built to withstand harsh industrial environments and ensure consistent performance.

Energy Savings and Efficiency

The sophisticated design of Vacon drives makes them ideal for industries looking to maximize energy savings and minimize operational costs.

Types of Vacon Variable Speed Drives

Vacon 100 Series

The Vacon 100 Series is perfect for applications that require high performance with a compact footprint. This series is known for its energy efficiency and reliable performance in a variety of industrial settings.

Vacon 20 Series

Designed for smaller scale applications, the Vacon 20 Series is a cost-effective solution that does not compromise on quality. It offers seamless integration and dependable motor control.

Vacon’s Integration Capabilities

Compatibility with Other Equipment

Vacon VSDs are designed to integrate seamlessly with existing systems, including programmable logic controllers (PLCs), sensors, and other automation devices. This ensures minimal disruption during installation and maintenance.

How to Choose the Right Variable Speed Drive

Factors to Consider

When selecting a VSD, consider the following:

- Application Type: Identify the type of process you need to control.

- Power Rating: Ensure the drive matches the power requirements of your motor.

- Environment: Choose a VSD that suits the environment where it will be installed (e.g., temperature, humidity).

Maintenance and Troubleshooting Tips

Common Issues and Solutions

Routine checks and proper maintenance are key to keeping VSDs in peak condition. Some common issues include:

- Overheating: Ensure that the VSD is adequately cooled and ventilated.

- Fault Codes: Familiarize yourself with the VSD’s error codes to troubleshoot effectively.

Future Trends in Variable Speed Drives

Innovations and Emerging Technologies

The future of VSDs involves more integrated technologies such as IoT (Internet of Things), machine learning for predictive maintenance, and even smarter algorithms for real-time adaptation to process changes.

Conclusion

Variable Speed Drives play an essential role in optimizing energy use, improving process control, and extending equipment life. Vacon, with its proven track record and innovative solutions, remains a top choice for industries looking to invest in reliable and efficient drive systems.